可吸附翹曲、鏤空工件、玻璃基板材料類型等作業物。

相較於傳統吸盤對於工件單一化規格吸附的特性,陶瓷真空吸盤的區域性吸附功能,有助於提升產線流暢度及其效能,亦可避免傳統吸盤易造成的刮傷及吸痕。

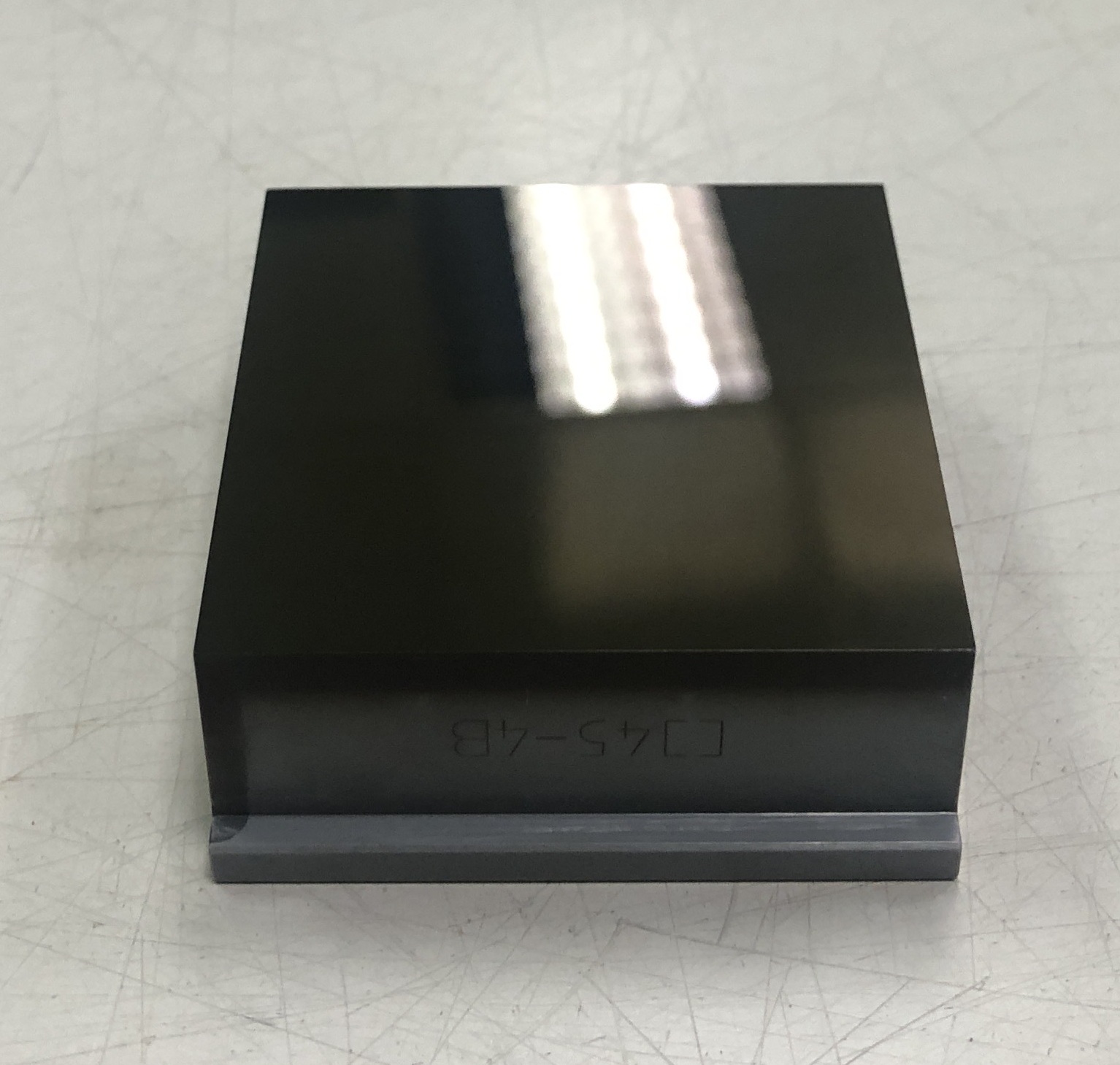

Our vacuum chucks are capable of holding warped/hollow workpieces and glass substrates.

Traditional chucks are typically manufactured to meet a single set of specifications. By comparison, our ceramic vacuum chucks offer regional adhesion. They are designed to enhance the continuity and efficiency of production lines while avoiding scratches and hold marks often produced by conventional chucks.

可吸附翹曲、鏤空工件、玻璃基板材料類型等作業物。

相較於傳統吸盤對於工件單一化規格吸附的特性,陶瓷真空吸盤的區域性吸附功能,

有助於提升產線流暢度及其效能,亦可避免傳統吸盤易造成的刮傷及吸痕。

Our vacuum chucks are capable of holding warped/hollow workpieces and glass substrates.

Traditional chucks are typically manufactured to meet a single set of specifications. By comparison, our ceramic vacuum chucks offer regional adhesion. They are designed to enhance the continuity and efficiency of production lines while avoiding scratches and hold marks often produced by conventional chucks.

III-V族wafer經由背面研磨減薄後進行微影、金屬化、刻蝕..等工藝,使用基座加熱至所需溫度後將其鍵合蠟溶解,再經由上下真空吸盤建立真空吸力後,使用步進馬達驅動方式向前移動進而與晶圓分離。

更多